8 Easy Facts About Roof Spandrel Panels Explained

Table of ContentsThe Best Strategy To Use For Insulated PanelsThe smart Trick of Insulated Spandrel Panel Detail That Nobody is Talking AboutThe Facts About Spandrel Panel Curtain Wall UncoveredThe 10-Second Trick For Spandrel InsulationThe Main Principles Of Insulated Spandrel Panel Detail Nhbc Spandrel Panels Things To Know Before You Buy

Occasionally, there are concerns associating with having way too much unrestrained daytime, sometimes referred to as glare. The challenge is to make every effort for the highest noticeable light transmittance (VT) as well as the least expensive solar warm gain coefficient (SHGC) while not stopping the glass from being too reflective when viewed from both the exterior and the interior, while managing glare.The devices must be completely set up in a factory as well as shipped to the website for installation on the structure. The devices are positioned on the floorings, packed in dog crates, making use of the tower crane as well as reduced right into location utilizing a smaller crane or raise had by the glazing specialist. The mullion dimensions tend to be slightly larger than a stick system because of their open area as contrasted to television shape of a common stick curtain wall surface area.

Units can be assembled in a factory while the architectural structure of the building is being built. Where stick systems call for several actions to set up and seal the wall surface, unitized walls get here on the site completely constructed enabling the floorings to be closed in much more promptly. Unitized systems also need less area on website for layout hence providing an advantage for city websites with space restrictions.

Kawneer Spandrel Panel Metal Spandrel Can Be Fun For Anyone

Solutions whose connecting legs lock likewise jeopardize the capacity of the system to accommodate activity. Some unitized styles are sensitive to little irregularities in the spacing of adjacent modules; as an example, if the component joints are a little out of tolerance, gaskets might not be correctly pressed as well as moisture defense may suffer.

This is where area labor have to seal in between adjacent devices to accomplish a weather tight wall. The interlocking legs of the straight mullions are the most essential user interface of a unitized system.

A Biased View of Kawneer Spandrel Panel Metal Spandrel

These upstanding legs have gaskets that seal against the walls of the bottom straight. Some styles offer one honest leg that supplies one line of protection against air and water infiltration. Extra robust systems will certainly give two upstanding legs with gaskets on both legs. A splice plate or silicone flashing that is installed at the top of both nearby devices as they are set up on the structure is commonly needed.

The stack joint is the straight joint where units from adjacent floorings meet. Positioning the stack joint at the sill of the vision glass (commonly 30" above the flooring) will reduce the measurement of the vertical mullions. This positioning makes use of the back span of the mullion over the anchoring point at the piece to counteract the deflection of the mullion listed below the piece.

Define that research laboratory tests are to be performed at an AAMA Accredited Laboratory center. Area Mock-up: For all drape wall surfaces, supply or customized, require construction as well as testing of an area mock-up agent of the wall/window setting up. This is finest scheduled prior to the release of store drawings for window production, to ensure that there is a chance to make layout adjustments based on the test performance of the field mock-up.

What Does Kawneer Spandrel Panel Metal Spandrel Mean?

Area testing of drape walls: Require the area testing website link of drape wall surfaces for air seepage as well as water infiltration resistance, for high quality guarantee of drape wall surface construction as well as installation. Call for several examinations with the very first test on initial setups and later tests at approximately 35%, 70% and at final completion to catch troubles early as well as to validate continued handiwork quality.

The details related to this section of the BEDG on the WBDG were created by committee and are intended solely as a method to show basic style and also construction principles only. Appropriate usage as well as application of the concepts highlighted in these details will certainly vary based upon performance factors to consider as well as environmental problems distinct per job as well as, as a result, do not stand for the last point of view or suggestion of the author of each area or the committee participants in charge of the growth of the WBDG.

Constant steel sill blinking at the base of the drape wall surface shields the wall surface framing listed below from leak via the curtain wall surface. Sill blinking must have upturned end dams as well as fully sealed corners. Intermediate horizontal ought to be wept to the outside and avoid water from draining pipes onto the head of the glazing device listed below.

4 Easy Facts About Kawneer Spandrel Panel Metal Spandrel Explained

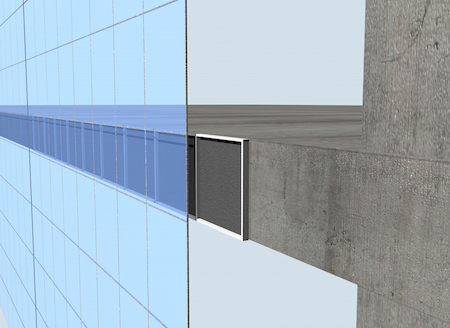

Spandrel glass adapters are used to decrease the deepness of the glazing pocket to fit reduced account of spandrel glass. Spandrel glass adapters should be totally bedded in sealer and also incorporated with glazing pocket edge seals to stop water leak from glazing pocket to structure interior. System measurement of breeding head and sill pop over to this web-site squeezed out profiles permits specified flooring to floor deflection at the stack joint.

Intermediate horizontals quit at the face of the upright system jamb participants at each end. Systems are hung from the top or face of check it out the nearby floor or building structure utilizing mated braces as well as field used bolts with a minimum of clearance for access as well as setting up. All links and also brackets located within the units shielded or key weather seal areas are secured with proper sealant materials throughout area installation.

The Only Guide for Spandrel Panel Window

non-heat-treated) or completely toughened up glass to remain in position till it can be replaced. Whether heat-strengthened or totally solidified, heat-treated glass products are generated in a similar style and using the very same processing equipment. The glass is warmed to about 650 C (1200 F), then force-cooled to create surface area and also edge compression.

As indicated in Figure 1, insulation is typically made use of in combination with spandrel glass. When the insulation is to be applied directly to the opacified surface area of the spandrel glass, it is very important to deal with a glass spandrel producer, along with the sticky and also insulation distributors, to make sure these products work with the opacifying material - spandrel panel detail.